Why learning about magnetic materials is so important?

Engineering materials are important in everyday life

because of their versatile structural properties. Prime physical properties of materials include electrical

properties; thermal properties; magnetic properties; and

optical properties. The magnetic properties of engineering materials are

diverse, and so are their uses in different applications.

Ex.: motors, telephones, medical applications, etc.

What is Magnetism?

Magnetism is a phenomenon by which a material exerts an either attractive or repulsive force on another. The basic source of magnetic force is the movement of electrically

charged particles. Thus magnetic behavior of a material can

be traced to the structure of atoms. Electrons in atoms have a planetary motion in that they go

around the nucleus. This orbital motion and its own spin

cause separate magnetic moments, which contribute to the

magnetic behavior of materials. Thus every material can

respond to a magnetic field. However, how a material responds depends

much on its atomic structure and determines whether a

material will be strongly or weakly magnetic.

Bohr Magneton:

Magnetic moment due to the spin of an electron is known as

Bohr magneton, MB.

where q is the charge on the electron, h – is Planck’s constant, and me – is the mass of the electron

Bohr magneton is the most fundamental magnetic moment.

Magnetic Dipoles:

Magnetic dipoles are found to exist in magnetic materials,

analogous to electric dipoles. A magnetic dipole is a small magnet composed of north and

south poles instead of positive and negative charges. Within a magnetic field, the force of the field exerts a torque

that tends to orient the dipoles with the field. Magnetic forces are generated by moving electrically

charged particles. These forces are in addition to any

electrostatic forces that may already exist. It is convenient to think of magnetic forces in terms of

distributed field, which is represented by imaginary lines.

These lines also indicate the direction of the force.

Types of Magnetism:

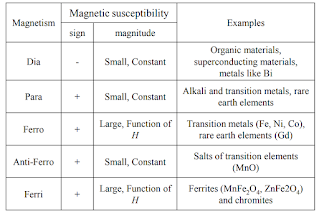

A material is magnetically characterized based on the way it can be

magnetized. This depends on the material’s magnetic susceptibility – its magnitude

and sign.

Dia-magnetism: very weak; exists ONLY in presence of an external

field.

Para-magnetism: slightly stronger; When an external field is applied

dipoles line up with the field, resulting in a positive magnetization.

However, the dipoles do not interact.

Ferro-magnetism: very strong; dipoles line up permanently upon

application of the external field. Has two sub-classes:-

Anti-ferro-magnetism: dipoles line up, but in opposite directions,

resulting in zero magnetization.

Ferri-magnetism: similar to anti-ferro-magnetism, but dipoles of

varying strength cannot cancel each other out.

|

| Types of Magnetism and their examples |

Temperature Effect:

Temperature does have a definite effect on a material’s magnetic

behavior. With rising temperatures, the magnitude of the atom's thermal

vibrations increases. This may lead to more randomization of

atomic magnetic moments as they are free to rotate. Usually, atomic thermal vibrations counteract forces between the

adjacent atomic dipole moments, resulting in dipole misalignment

up to some extent both in the presence and absence of an external field. As a consequence of it, saturation magnetization initially

decreases gradually, then suddenly drops to zero at a temperature

called Curie temperature, Tc. The magnitude of the Curie temperature is dependent on the

material. For example: for cobalt – 1120 ˚C, for nickel – 335 ˚C,

for iron – 768 ˚C, and for Fe3O4 – 585 ˚C.

Magnetic Domains:

In addition to susceptibility differences, the different types of

magnetism can be distinguished by the structure of the magnetic

dipoles in regions called domains. Each domain consists of magnetic moments that are aligned,

giving rise to a permanent net magnetic moment per domain. Each of these domains is separated from the rest by domain

boundaries/domain walls. Boundaries, also called Bloch walls,

are narrow zones in which the direction of the magnetic moment

gradually and continuously changes from that of one domain to

that of the next. The domains are typically very small about 50 μm or less, while

the Bloch walls are about 100 nm thick. For a poly-crystalline

specimen, each grain may have more than one microscopic-sized

domain. Domains exist even in absence of an external field.

The average magnetic induction of a ferromagnetic material is

intimately related to the domain structure. When a magnetic field is imposed on the material, domains that

are nearly lined up with the field grow at the expense of

unaligned domains. This process continues until only the most

favorably oriented domains remain. For the domains to grow, the Bloch walls must move, the

external field provides the force required for this moment. When the domain growth is completed, a further increase in the

magnetic field causes the domains to rotate and align parallel to

the applied field. At this instant material reaches saturation

magnetization and no further increase will take place in

increasing the strength of the external field.

|

| Magnetization vs Magnetic Field (M-H Plot) |

Magnetic Hysteresis:

Once magnetic saturation has been achieved, a decrease in the

applied field back to zero results in a macroscopically permanent

or residual magnetization, known as remanence, Mr

. The

corresponding induction, Br, is called retentivity or remanent

induction of the magnetic material. This effect of retardation by the material is called hysteresis. The magnetic field strength needed to bring the induced

magnetization to zero is termed coercivity, Hc. This must be

applied anti-parallel to the original field. A further increase in the field in the opposite direction results in a

maximum induction in the opposite direction. The field can once

again be reversed, and the field-magnetization loop can be closed, This loop is known as the hysteresis loop or B-H plot, or M- H plot.

|

| Magnetic Hysteresis |

Semi-Hard Magnets:

Once the area within the hysteresis loop represents the energy

loss per unit volume of material for one cycle. The coercivity of the material is a micro-structure-sensitive

property. This dependence is known as magnetic shape

anisotropy. The coercivity of recording materials needs to be smaller than

that for others since data written onto a data storage medium

should be erasable. On the other hand, the coercivity values

should be higher since the data need to be retained. Thus such

materials are called magnetically semi-hard.

Ex.: Hard ferrites based on Ba, CrO2

, γ-Fe2O3

; alloys based on

Co-Pt-Ta-Cr, Fe-Pt and Fe-Pd, etc

Soft Magnets:

Soft magnets are characterized by low coercive forces and

high magnetic permeabilities and are easily magnetized and

de-magnetized. They generally exhibit small hysteresis losses. Application of soft magnets includes cores for electromagnets,

electric motors, transformers, generators, and other

electrical equipment.

Ex.: ingot iron, low-carbon steel, Silicon iron, superalloy

(80% Ni-5% Mo-Fe), 45 Permalloy (55%Fe-45%Ni), 2-79

Permalloy (79% Ni-4% Mo-Fe), MnZn ferrite / Ferroxcube

A (48% MnFe2O4

-52%ZnFe2O4

), NiZn ferrite / Ferroxcube

B (36% NiFe2O4

-64% ZnFe2O4

), etc.

Hard Magnets:

Hard magnets are characterized by high remanent

inductions and high coercivities. These are also called permanent magnets or hard magnets. These are found useful in many applications including

fractional horse-power motors, automobiles, audio and

video recorders, earphones, computer peripherals, and

clocks. They generally exhibit large hysteresis losses.

Ex.: Co-steel, Tungsten steel, SmCo5, Nd2Fe14B, ferrite

BaO6Fe2O3, Cunife (60% Cu 20% Ni-20% Fe), Alnico

(alloy of Al, Ni, Co, and Fe), etc.