Why are single-phase induction motors called fractional KW motors?

Single-phase Induction motors are called fractional KW motors because they are widely manufactured in fractional KW capacity and used for domestic and commercial purposes. These motors are not self-starting. To start these motors additional winding so-called auxiliary winding is provided, once the motor started then it runs normally. The winding used normally in the stator of the single-phase induction motor (IM) is a distributed one. The rotor is of squirrel cage type, which is a cheap one, as the rating of this type of motor is low, unlike that for a three-phase IM.

Why Single phase induction motors are not self-starting?

As the stator

winding is fed from a single-phase supply, the flux in the air gap is alternating only, not a

synchronously rotating one produced by a poly-phase (maybe two- or three-) winding in

the stator of IM. This type of alternating field cannot produce a torque if the rotor is stationary (ω r = 0.0 ). So, a single-phase IM is not self-starting, unlike a

three-phase one. However, as shown later, if the rotor is initially given some torque in

either direction (ω r ≠ 0.0 ), then immediately a torque is produced in the motor. The

motor then accelerates to its final speed, which is lower than its synchronous speed.

|

| Single phase Induction Motor |

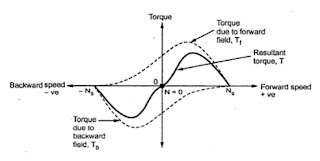

Double Field Revolving Theory :

It explains the not self-starting nature of 1 phase IM. When the stator winding (distributed one as stated earlier) carries a sinusoidal current

(being fed from a single-phase supply), a sinusoidal space distributed mmf, whose peak

or maximum value pulsates (alternates) with time, is produced in the air gap. This

sinusoidally varying flux (φ ) is the sum of two rotating fluxes or fields, the magnitude of

which is equal to half the value of the alternating flux (φ/2), and both the fluxes rotating

synchronously at speed, (Ns) in opposite directions. The flux or field rotating at synchronous speed, say, in the anticlockwise direction,

i.e. the same direction, as that of the motor (rotor) taken as positive induces emf (voltage)

in the rotor conductors. The rotor is a squirrel cage with bars short-circuited via end

rings. The current flow in the rotor conductors and the electromagnetic torque are

produced in the same direction as given above, which is termed assistive (+ve). The

other part of the flux or field rotates at the same speed in the opposite (clockwise) direction,

taken as negative. So, the torque produced by this field is negative (-ve), as it is in the

clockwise direction, the same as that of the direction of rotation of this field. Two torques are

in the opposite direction, and the resultant (total) torque is the difference between the two

torques produced.

|

| Speed-Torque characteristics of Single phase Induction Motor |

If the forward slip is "s" then the backward slip is given by "2-s".At starting

Forward torque Tf=Backward torque Tb

Therefore fails to start but if we provide some initial torque in any direction, the motor starts to rotate in that direction.

Circuit Diagram :

|

| Circuit Diagram of Single phase Induction Motor |

Starting Methods:

The single-phase IM has no starting torque but has resultant torque, when it rotates at

any other speed, except synchronous speed. It is also known that in a balanced two-phase

IM having two windings, each having an equal number of turns and placed at a space angle

of 90 degrees (electrical), and are fed from a balanced two-phase supply, with two voltages

equal in magnitude, at an angle of 90 degrees, the rotating magnetic fields are produced, as in a

three-phase IM. So, in a single-phase IM, if

an auxiliary winding is introduced in the stator, in addition to the main winding, but

placed at a space angle of 90 degrees (electrical), starting torque is produced.

Resistance Split Phase Induction Motor :

Auxiliary winding with high resistance in series is to be added along

with the main winding in the stator. This winding has a higher resistance to reactance (Ra/Xa) ratio as compared to that in the main winding and is placed at a space angle of 90 degrees from the main winding. The current (Ia) in the auxiliary

winding lags the voltage (V) by an angle, φ a, which is small, whereas the current (Im)

in the main winding lags the voltage (V) by an angle, φ m, which is nearly 90 degree. The

phase angle between the two currents is (90°

−φ a), which should be at least. This

results in a small amount of starting torque. The switch, S (centrifugal switch) is in series

with the auxiliary winding. It automatically cuts out the auxiliary or starting winding,

when the motor attains a speed close to full load speed. The motor has a starting torque of

100−200% of full load torque, with the starting current as 5-7 times the full load current. The changeover occurs when the auxiliary winding is switched off.

|

| Resistance Split Phase Induction Motor |

Capacitor Start Induction Motor:

A capacitor along with a centrifugal switch is connected in series with the

auxiliary winding, which is being used here as a starting winding. The capacitor may be

rated only for intermittent duty, the cost of which decreases, as it is used only at the time

of starting. This motor is used in applications, such as compressors, conveyors, machine

tool drives, refrigeration, and air-conditioning equipment, etc.

|

| Capacitor Start Induction Motor |

Capacitor start Capacitor Run Induction Motor:

Two capacitors Cs for starting, and Cr for running, are

used. The first capacitor is rated for intermittent duty, being used

only for starting. A centrifugal switch is also needed here. The second one is to be rated

for continuous duty, as it is used for running. The phase difference

between the two currents is (φa+φm>90°) in the first case (starting), while it is 90 degrees for the second case (running). In the second case, the motor is a balanced two-phase one, the two

windings having the same number of turns and other conditions are also

satisfied. So, only the forward rotating field is present, and no backward rotating field

exists. The efficiency of the motor under this condition is higher. Hence, using two

capacitors, the performance of the motor improves both at the time of starting and then

running. This motor is used in applications, such as compressors, refrigerators, etc.

|

| Capacitor start Capacitor Run Induction Motor |

|

| Torque-Speed Characteristics of a C.S.C.R. IM |

Shaded Pole Induction Motor:

This is a single-phase

induction motor, with main winding in the stator. A small portion of each pole is

covered with a short-circuited, single-turn copper coil called the shading coil. The

sinusoidally varying flux created by ac (single-phase) excitation of the main winding

induces emf in the shading coil. As a result, induced currents flow in the shading coil

producing their own flux in the shaded portion of the pole. the net flux in the shaded portion

of the pole (φ sp ) lags the flux (φ m′) in the unshaded portion of the pole resulting in a net

torque, which causes the rotor to rotate from the unshaded to the shaded portion of the

pole. The motor thus has a definite direction of rotation, which cannot be reversed. The reversal of the direction of rotation, where desired, can be achieved by providing

two shading coils, one on each end of every pole, and by open-circuiting one set of

shading coils and by short-circuiting the other set.

The fact that the shaded-pole motor is a single-winding (no auxiliary winding) self-starting

one, makes it less costly and results in rugged construction. The motor has low

efficiency and is usually available in the range of 1/300 to 1/20 kW. It is used for domestic

fans, record players and tape recorders, humidifiers, slide projectors, small business

machines, etc. The shaded-pole principle is used in starting electric clocks and other

single-phase synchronous timing motors.

|

| Shaded Pole Induction Motor |

|

| Shaded Pole Induction Motor- Phasor Diagram |